Reliability In Action

Reliability In Action

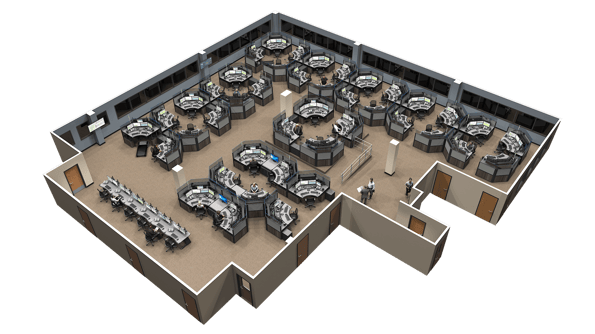

Transportation surveillance, security, and technology require close monitoring for emergencies and anomalies that contribute to service delays. Operator alertness is a critical factor in executing safe and efficient transportation management of local, national, and international infrastructure.

Where there is no room for errors, our ergonomically designed transport control room consoles have been adapted to address individual environmental factors such as lighting, temperature, air quality, and height by the operator, enabling peak performance. Our design strategy also considers how people interact with each other, how they are

routed throughout the control room to avoid unnecessary

distractions, and how people need to function during emergencies.

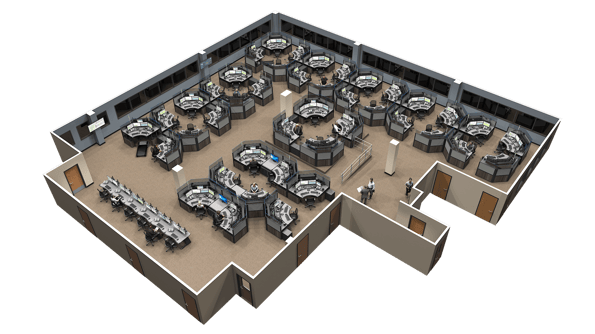

Minimal Disruption with Live Cutovers

Evans understands your operations run 24/7, 365 with no downtime to install a new transport control room. We perform ‘Live Cutovers’ that require zero downtime and minimal disruptions to surrounding areas, allowing your facility to fully operate during installation.

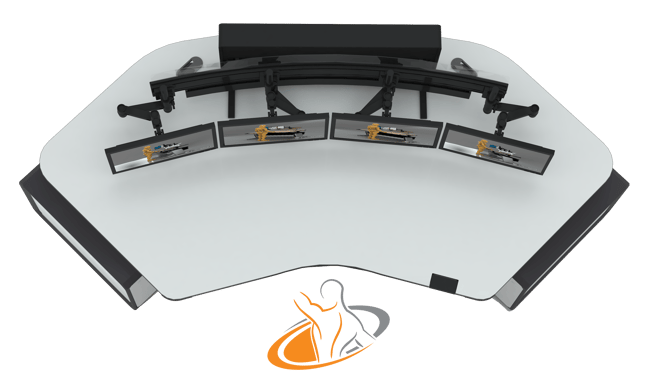

Future Proof Consoles

Our complete range of consoles is future-proof, providing dynamic flexibility to support your technology, equipment, or operational changes, and upgrades; creating value over time.

Transportation Safety Compliance

Our teams have clearance to some of the highest levels of national security. They have the clearance to work in high-security, highly-classified areas – where sensitive information is present. We recognize we may be working in secure classified areas, and work with you to ensure our team members understand and fully comply with all security protocols.

We are your experts.

Reliability In Action

Reliability In Action